Share this link via

Or copy link

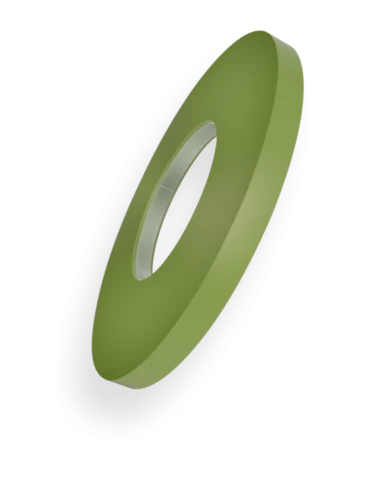

Solid Color Edgebands

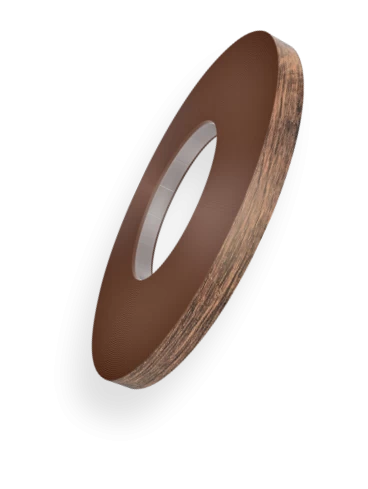

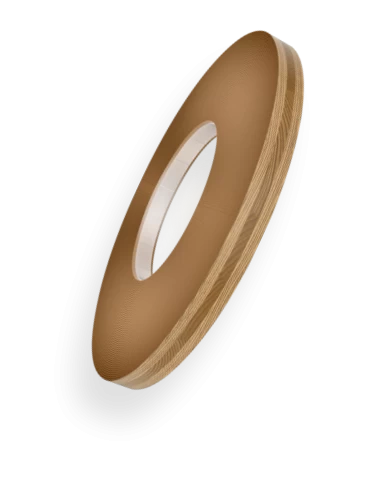

Woodgrain Edgebands

Fantasy Decor Edgebands

Perfect Gloss Edgebands

Design Edgebands

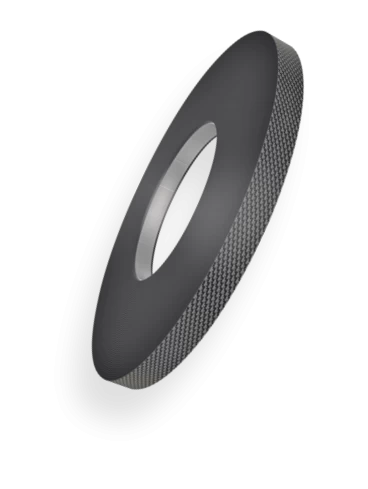

Technological Edgebands

The edge band is an aesthetic detail that allows the furniture to be more durable and long-lasting while at the same time gaining a more elegant appearance. If we define it in a very broad framework, we can say that the edge bands produced to prevent the raw edges of the furniture from being exposed are a kind of coating product.

In furniture production, edging, which can be preferred in accordance with the design in harmony with the model, colour, pattern and texture of the furniture, prevent the raw edges of the furniture from being exposed, and thus the furniture gains a holistic design approach both within itself and at the point where it is compatible with the space. Untreated edges create a sense of incompleteness visually and tactilely. Edge bands designed to prevent this feeling also allow functional perfection by closing the edge of furniture produced with chipboard or MDF, making them more resistant to factors such as impact, yellowing and moisture.

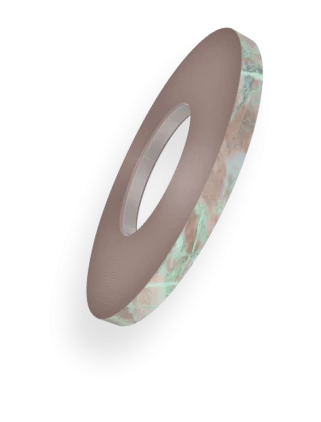

The first thermoplastic material ever used for edging in the industry. Ideal for machining; easy to bond and trim. Flexible material for straightforward processing.

Chlorine-free. Good impact and heat resistance. Can be thermally utilised and incinerated in authorised facilities. Easy to process. ABS edging is preferred in Europe.

These “acrylic” edges are mainly used in applications focused on design. High scratch resistance, durable and resistant. Good light-fastness. For perfect, seamless edges. Ideal for 3D effects thanks to glass-like transparency.